Page 4 - Stock Pressure Seal Product Catalog

P. 4

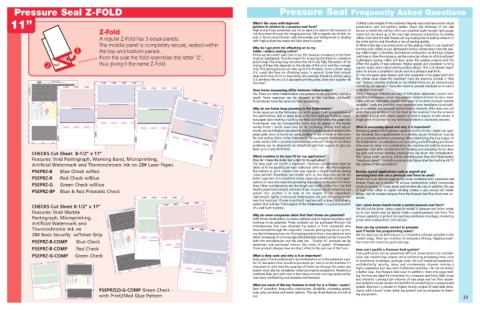

Pressure Seal Z-FOLD Pressure Seal Frequently Asked Questions

11” What’s the issue with high-end 1) What is the weight of the machine? Heavier machines have more robust

construction and will perform better. Check the thickness of the side

printers in relation to a pressure seal form?

Z-Fold High-end printers sometimes use oils or agents to assist in the transport of frames to which the sealing rollers are attached. Light weight, light gauge

the document through the imaging process. Oils or agents can inhibit the

metal will not stand up to the very high pressures endured by the sealing

A regular Z-Fold has 3 equal panels. seal. A forms manufacturer with knowledge and background in dealing rollers. Over time the side frames will sag causing loss of sealing pressure in

with high-end printer issues will help ensure success.

the roller section and therefore a loss of sealing quality.

The middle panel is completely secure, sealed within 2) What is the size and construction of the sealing rollers in the machine?

the top and bottom panels. Why do I get print ink offsetting on to my Are they solid rollers or just lightweight hollow construction? Are the seal-

folder / sealers sealing rollers?

ing rollers larger in diameter and heavier construction on the high volume

From the side the fold resembles the letter “Z”, Forms use inks which take time to dry. The moisture consistency of the form machines or does the company use the same size rollers on all its machines?

must be maintained. Thus the reason for wrapping the forms in a moisture

Lightweight sealing rollers will bow under the sealing pressure and this

thus giving it the name Z-Fold. proof wrap. This wrap may not allow the ink to dry fully. The extent of the affect the quality of seal achieved. Higher speeds and consistent running

drying of these inks depends on the density of the color and the coverage

require larger, more robust sealing section design. This is of utmost impor-

area. This drying process can take up to 6 to 8 weeks. Forms printed using

U.V. cured inks have no offsetting issues. In general, forms that contain tance to ensure a consistent, secure seal on a pressure seal form.

large solid areas of ink or have heavy ink coverage should be printed using 3) How are paper jams cleared and how accessible is the paper path and

U.V. printing inks on a U.V. equipped printing press. Does your supplier do the critical areas inside the machine? Does the machine provide a “kick

this now? out” feature whereby misfeeds or mis-folded forms can be automatically

cleared by the operator? Does the machine provide feedback as to where

Does forms sequencing differ between folder/sealers? a mis-feed occurred?

Yes. There are some folder/sealers that process forms differently and as a Other important features are ease of fold plate adjustment, sound level,

result, forms sequence can be reversed at the out-feed. InfoSealPS size of in-feed hopper, power requirement. Options to look for are a reset-

folder/sealers have the same out-feed sequencing. table and non-resettable counter and types of outfeed conveyor systems

available. Lastly but probably most important post installation is availabil-

Why do my forms keep jamming in the folder/sealer? ity of a reliable and properly trained service network. Who does one call

Forms issues can be the following: curl in the paper, floating registration of when there is a problem? Is it the form or the machine? Can the problem

fold perforations, dull or dead spots in the fold assist perforations, exces- be solved quickly with phone support or does it require on-site service. A

sive paper dust creating a build-up on feed and fold rollers, the paper and single point of contact for any technical problem is absolutely essential.

folder/sealer may be incompatible, forms may be placed in the feeder

wrong Folder / sealer issues may be the following: Wrong feed adjust- What is processing speed and why is it important?

ments, wrong fold plate adjustments, bent fold plates, chad or debris in the Processing speed is the optimum speed at which a folder / sealer can oper-

paper path, worn or burnt out parts, buildup of ink or toner on the trans- ate. However, like a speedometer on a vehicle, certain limitations must be

fer and sealing rollers. Is the folder/sealer being properly maintained and set to maintain consistent processing. When identifying the true output of

under service with a properly trained service network? Many of the above the folder/sealer considerations such as loading and off-loading and down-

problems can be diagnosed via telephone technical support to get you time must be taken into consideration. No machine will yield its maximum

back up in a very short time. speed per hour after consideration for loading and unloading forms, clear-

CHECKS Cut Sheet 8-1/2” x 11” ing jams and normal workday interruptions are taken into consideration.

Which machine is the best fit for my application? The “actual yield” per hour will be something less than the folder/sealers

Features: Void Pantograph, Warning Band, Microprinting, (How do I choose the model that is right for my application)? “maximum speed”. Using this approximate figure does the machine still fit

Artificial Watermark and Thermochromic Ink on 28# Laser Paper. The duty cycle per month is important. However, consideration must be the volume of the application?

taken as to the quantity per each individual print run. Are there seasonal

PSEPRZ-B Blue Check w/Red fluctuations in print volume that may require a larger machine during Besides typical applications such as payroll and

those periods? Sometimes two smaller units vs. one large one can be the invoicing how else can a pressure seal form be used?

PSEPRZ-R Red Check w/Blue better approach. It is sometimes better, especially on mission critical appli- Direct mail is an obvious opportunity when combined with a pressure seal

cations, to have two machines providing redundancy in the event of down format. There are a number of unique constructions which incorporate

PSEPRZ-G Green Check w/Blue time. Other considerations are: the length and width of the form, the fold return envelopes, ID Cards, labels and window die cuts. In addition, the use

depths, paper basis weight, and ease of use. A good way of comparing one

PSEPRZ-BP Blue & Red Prismatic Check system over another is to look at the weight of the equipment. of high color offset or digital printing creates a very unique self mailer

design. Ask for product samples from the Pressure Seal Plus direct mail col-

Lightweight, lightly constructed folder/sealers are just not going to last lection.

over the long haul. Choose a well built machine with a heavy duty sealing

section that will last. Total weight of the folder/sealer is a good indication

CHECKS Cut Sheet 8-1/2” x 11” of a well built machine. Can I place loose inserts inside a sealed pressure seal form?

Yes this can be done. Using a specific model of pressure seal folder sealer

Features: Void Marble up to two inserts may be placed inside a sealed pressure seal form. This

Why do some companies claim that their forms are patented? unique capability is perfect for inserting remittance envelopes, marketing

Pantograph, Microprinting, Both forms construction, co-hesive patterns and co-hesives have been and pieces and creating direct mail designs.

Artificial Watermark and continue to be patented. These products can be purchased through the

Thermochromic Ink on manufacturers that have obtained the patent or from companies who How can my customer convert to pressure

have licensed through the originator. However, pricing may be at a premi-

seal if he/she has programming issues?

28# Basic Security w/Toner Grip. um due to licensing fees, etc. Purchasing product from a manufacturer who We can assist you by directing you to compatible software available in the

either knowingly or unknowingly sells patented product can be trouble for market today. There are a number of companies offering “digital presets”

PSEPRZ-B-COMP Blue Check both the manufacturer and the sales rep. “Similar to” products can be that make the transition quick and easy.

developed and purchased without the worry of patent infringement.

PSEPRZ-R-COMP Red Check These product changes have no direct affect to the end use of the form. How can I justify a Pressure Seal system?

Cost justification can be sometimes difficult. Some factors for consider-

PSEPRZ-G-COMP Green Check What is duty cycle and why is it so important? ation are: maximizing volume while minimizing processing time, costs

Duty cycle is the manufacturer’s recommendation as to the maximum num- of traditional envelopes, postage costs, old and outdated equipment,

ber of documents that should be processed per month on the machine. It’s confidentiality, security, labor, and maintenance. Anyone running a

important to note that the quantity of forms run through the sealer per highly expensive but very slow traditional inserting line can be shown

session must also be considered when purchasing equipment. Reaching a a better way...the Pressure Seal way! In addition, most one page mail-

machines duty cycle with one or two heavy volume runs may cause prema- ing formats are ideal for conversion to a pressure seal form. Mail shops

ture wear, overheating and excessive maintenance.

and implants running high volumes of one page mail on their expen-

sive inserters should review the benefits of converting to a pressure seal

What are some of the key features to look for in a folder / sealer? system. Emphasis is placed on higher hourly output of mail able docu-

PSEPRZ(2)-G-COMP Green Check - Ease of operation, heavy-duty construction, durability, processing speed, ments with a much lower initial equipment cost as compared to insert-

with Print2Mail Glue Pattern duty cycle, purchase and rental options. The top three features to look at ing equipment. 23

are: